BioSolids Composting

In 1990 the city constructed the region’s first composting facility for municipal biosolids. These are byproducts of municipal wastewater treatment. Prior to this process, treated and de-watered biosolids (sludge) were made available to the general public. New concerns and regulations led the city to try this innovative form of biosolids management. Today the facility produces about 4800 cubic yards of compost annually. It is a “Class A” product that is unrestricted in its horticultural use and can be obtained from area landscapers.

Located at 3500 Julia Street, the 18-acre facility is staffed by two compost operators. It is here that the annual average of 18,000 wet-pounds per day, 365 days per year, of biosolids are processed during the 51-day journey through the plant. The compost is then ready for wholesale purchase by our vendor(s).

The process used is called Aerated Static Pile Composting because non-moving, “static”, piles are built and aerated for the composting to occur. While the facility has been on line since 1990, several major additions and modifications have been made. They include covered chip storage, outside pile bays, aerated coring, additional conveying, and mixing and screening equipment. Other essential equipment includes 2 front-end loaders of 3 cubic yard capacity—used for building and tearing down the piles.

The city does not sell compost directly to the public.

Coeur d'Green Compost can be purchased from one of the following resellers:

Northland Nursery (208) 773-3247, located at: 8093 W. Prairie Ave., Post Falls, ID 83854

Rockhound Landscape Supply (208) 773-4346, located at: 2591 N. Hwy 41, Post Falls, ID 83854

Tumble Stone (208) 762-3206, located at: 13131 N. Government Way, Hayden, ID 83835

Main Composting Building

How Composting Works

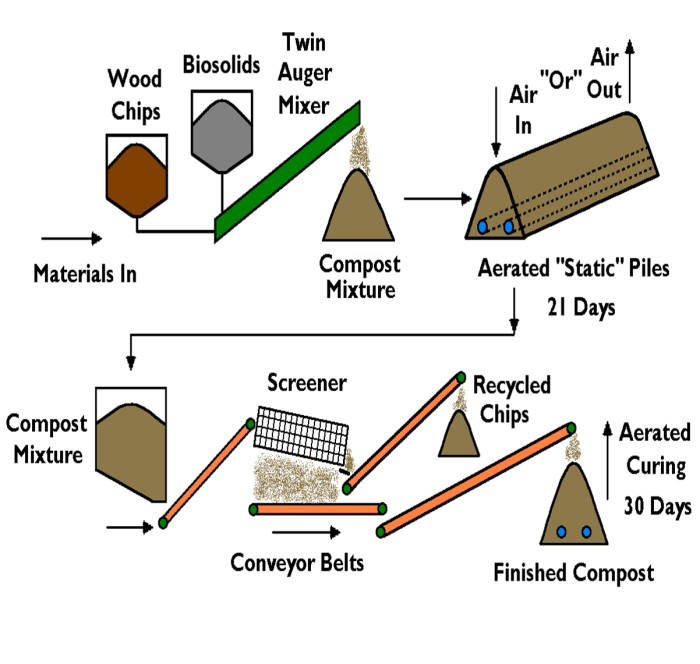

De-watered biosolids from the city’s wastewater treatment plant are brought to the compost facility. Here it is mixed with a bulking agent—wood chips.

The wood chips provide three functions:

1) They promote a loose mix with many spaces between the chips to allow air to circulate. This provides the needed oxygen to support the compost process and the high temperatures needed for EPA requirements.

2) They are used to adjust the mixed pile moisture content to an optimum ratio.

3) They are used to adjust the nutrient balance of the mix to promote ideal compost operation.

The compost mix is then formed into piles—10 piles inside and up to 6 on the outside. Perforated air pipes are located at the bottoms of the piles. Air is either forced into or sucked from piles. Drawing air through the piles is done as both a temperature and odor control measure. As the biological activity takes place, the organic material in the biosolids is decomposed, giving off heat. The temperature must rise to at least 131° F for 3 consecutive days and average 113° F for 14 days. The mix remains in the piles for a total of 21 days. Prior to screening, they are slowly allowed to cool to ambient temperature.

Chip Hopper & Twin Auger Mixer

A front-end loader then loads the pile contents into a screening unit to separate the majority of the wood chips from the compost. The wood chips are recycled for reuse with the next batch of incoming biosolids.

The screened compost looks like an organic topsoil which is placed in aerated curing piles for 30 days prior to sale. Curing occurs under covered storage.

Aerated “Static” Composting Piles

During heavy biosolids production in the summer months when phosphorus removal at the advanced wastewater treatment plant takes place, composting is done on the exterior as well as inside the main building.

Odor control is accomplished using compost-bed biofilters that act as biological odor scrubbers. These have their greatest value when drawing air through the piles—rather than blowing air into them—when ammonia is present.

The final product is sold wholesale to landscaping contractors who sell retail to the public.

It is recommended for use as an amendment for top soil, potting soil, nurseries, golf courses, land reclamation projects, humus for sandy soils, and vegetable gardens. It is about 60% biosolids and 40% wood product.

Screening Unit

Finished Compost

Recommended Uses

Compost contains essential micro-nutrients and looks, smells and has a texture similar to commercial soil conditioners. Although compost fertilizer values (N, P & K) may be less than chemical fertilizers, their release is slower and may be more beneficial. The organics in compost provide valuable water retaining capabilities in soil. Representative properties of compost are:

pH, 7.32 SU

Nitrogen, (as N) 3.3%

Phosphorus, (as P2O5) 3.5%

Potassium, (as K2O) .27%

C.E.C., meq/100 grms 58

Organic Matter, 45%

Bulk Density, 35-40 lb/ft³

Coeur d’Green™ meets all U.S. Environmental Protection Agency regulations for unrestricted use in the areas of agriculture, agronomy, and horticulture. It may be used on vegetable gardens of all types. The product is regulated under the city’s wastewater discharge permit and is regularly tested for toxicants and for pathogenicity. The low levels of toxicants and pathogens qualify our product as Class “A” by the E.P.A.

Coeur d’Green™ is a registered trademark to the City of Coeur d’Alene, Idaho. TM#13504. Coeur d’Green™ is also licensed with the State of Idaho as a soil amendment product. Certificate #2640.

Compost Plant Profile

For guided group tours of either the compost facility or the advanced wastewater treatment plant, contact our main office at the phone number found on our Administration page.